- Economy Insights

- Posts

- Paper, Pulp, and Packaging

Paper, Pulp, and Packaging

The Materials Moving the Online Marketplace

The rapid rise of e-commerce has transformed how goods are bought and sold – and it’s also reshaping the packaging industry. Every day, millions of parcels leave warehouses bound for consumers’ doorsteps, generating unprecedented demand for shipping materials like cardboard boxes, paper mailers, and cushioning. In 2022, global parcel shipments reached 161 billion packages, up from 159 billion in 2021. The world’s top online retail markets – China, the United States, the United Kingdom, Japan, and Germany – are at the epicenter of this boom, collectively contributing the majority of e-commerce sales and parcel volume. This report examines how the growth of e-commerce in these five markets is driving soaring demand for paper, pulp, and packaging materials, and how industry players are responding with sustainable, innovative solutions. Key trends, country-specific statistics, corporate initiatives, and emerging challenges in sustainable packaging are discussed, with charts and tables illustrating e-commerce growth, packaging consumption, and sustainability efforts.

E-Commerce Growth Driving Packaging Demand

E-commerce has become a multi-trillion dollar force in global retail. In 2023, online retail sales worldwide were estimated around $5–6 trillion, accounting for roughly 19.5% of all retail sales. This share has climbed steadily (from about 10% of retail in 2017) as consumers increasingly shop online for everything from electronics to groceries. The growth is especially concentrated in a few markets. China and the U.S. dominate global e-commerce by sheer volume (Figure 1), with China alone representing about 50% of global online sales. China’s online retail market was over ¥15.5 trillion in 2024 (≈$2.16 trillion), while the U.S. market reached roughly $1.16 trillion in 2023. The UK, Japan, and Germany each have online sales on the order of $100–200 billion annually, making them the largest e-commerce markets in Europe and Asia outside China.

Figure 1: Retail E-Commerce Sales in 2023 (USD billions) for the top five national markets. China’s online sales far exceed those of other countries, reflecting its status as the world’s largest e-commerce market.

The surge in online shopping has a direct knock-on effect: demand for shipping and packaging materials has skyrocketed. Every item purchased online must be packaged and delivered, often individually, leading to an explosion in parcel shipments. Globally, the e-commerce packaging market was about $77 billion in 2024 and is projected to grow to $125 billion by 2029 (about 10% CAGR) – a growth rate several times higher than traditional retail packaging growth. Corrugated cardboard boxes, padded mailers, packing paper, and other materials are being produced in record quantities to keep up with fulfillment needs. According to industry research, e-commerce packaging (including corrugated boxes, mailers, tapes, and protective materials) was growing at double-digit rates pre-2020, and the pandemic only accelerated this trend as consumers shifted to online purchasing. Even with some normalization post-pandemic, online retail continues to expand faster than brick-and-mortar sales, fueling ongoing high demand for packaging.

One illustration of this demand is the corrugated box industry. Corrugated fiberboard (the material in cardboard boxes) is a staple of e-commerce shipping due to its strength and light weight. By 2018 it was estimated that upwards of $20 billion worth of corrugated materials were used annually for e-commerce globally, and that figure has grown substantially since. During the COVID-19 pandemic, box manufacturers struggled to keep up with orders as parcel volumes spiked. In the U.S., demand for corrugated and paperboard boxes reached $47 billion in 2024 and continues to rise as e-commerce remains elevated. Similarly, packaging producers in other countries ramped up capacity – for example, International Paper invested €23 million in 2023 to expand two French corrugated packaging plants by 50–60%, specifically to meet growing e-commerce demand for sustainable boxes.

Critically, e-commerce requires packaging that can withstand complex logistics chains. A typical online order may be handled 20 times or more in transit – traveling through automated warehouses, delivery trucks, and doorstep drop-offs – so packaging must be robust and secure. This has driven innovation in package design (to protect items through bumps and drops) as well as the use of protective fillers. It also means more packaging per item than traditional retail: a product on a store shelf might only have its primary package, whereas that same product sold online gets an additional shipping box or mailer, cushioning, and tape. The result is a higher volume of packaging waste reaching consumers, which brings sustainability to the forefront.

The Role of Paper and Pulp in Sustainable Packaging

As e-commerce grows, there is increasing scrutiny on the sustainability of all this packaging. Here, paper and pulp-based materials play a pivotal role. The majority of e-commerce parcels today ship in fiber-based packaging – corrugated cardboard boxes, paperboard envelopes, paper cushioning, etc. – which is renewable, reusable, and recyclable. Paper and paperboard materials made from wood pulp are valued for their versatility and environmental profile. In fact, they account for one of the largest shares of the e-commerce packaging market by material, second only to plastics. Paper-based packaging can serve many functions: corrugated board provides sturdy shipping boxes; kraft paper and paperboard are used in eco-friendly void fill and padded mailers; and even tape and labels can be paper-based.

A key advantage of fiber packaging is its high recyclability. Paper and cardboard packaging boast the highest recycling rates among all packaging materials – reaching over 83% recycling rate for paper packaging in regions like Europe. In the U.S., old corrugated cardboard is recycled at an estimated 71–76% rate, and Europe’s overall paper recycling rate is nearly 80%. This far outstrips plastics, which often have recycling rates below 30% (and under 15% in the U.S. for plastic packaging). In practice, this means the corrugated box left on a consumer’s doorstep is very likely to end up being collected, pulped, and remade into new packaging – a closed-loop cycle. Major packaging firms operate large-scale recycling networks (for example, UK-based DS Smith not only makes boxes but also collects used boxes for recycling). In China, paper recycling has grown as well: Chinese paper companies have relied on recovered paper as a feedstock, and domestic recycling has expanded, especially after imports of waste paper were restricted. The circular nature of paper packaging – from tree, to box, to recycling bin, and back to new box – makes it a linchpin of sustainable e-commerce logistics.

Beyond recyclability, paper is biodegradable and sourced from renewable forestry, giving it a smaller environmental footprint than fossil-based plastics. Leading packaging companies emphasize sourcing from sustainably managed forests and increasing the recycled content in boxes. International Paper, for instance, markets its corrugated packaging as part of a “low-carbon, circular” value chain, made from renewable fiber and recycled content. Many e-commerce retailers now prefer paper mailers and cardboard over plastic mailers or foam packaging to align with sustainability goals. According to one industry study, paper & paperboard are widely chosen for e-commerce packaging due to their cost-effectiveness, versatility, and ease of recycling.

The push for sustainability is also evident in consumer preferences: shoppers increasingly want earth-friendly packaging. In the UK, a recent survey found 4 in 5 online shoppers prefer products to arrive in paper or cardboard packaging rather than plastic, and 1 in 5 said they would even pay extra for plastic-free packaging. Over two-thirds of consumers said receiving an item in paper packaging improves their perception of the retailer’s sustainability. This is a strong signal to brands that investing in paper-based, recyclable packaging can be a competitive advantage. (By contrast, excessive or non-recyclable packaging can drive customers away – 26% of UK online shoppers said they would stop ordering from a company if the packaging was excessive, and 22% would do so if the packaging wasn’t recyclable.) These attitudes are pushing e-commerce companies to swap plastic mailers for paper mailers, eliminate unnecessary filler, and use packaging that communicates a “green” image to consumers.

In summary, the paper and pulp industry underpins the e-commerce packaging supply chain, providing sustainable materials at huge scale. But the surge in demand also raises challenges: ensuring enough supply of recycled fiber, improving recycling infrastructure in regions where it’s lacking, and continuing to innovate paper-based solutions for uses where plastic still dominates (for example, cushioning liquids or insulating cold shipments). We will see next how the top e-commerce countries are navigating these issues and leveraging paper packaging in their own markets.

Top Five E-Commerce Markets: Key Statistics and Trends

The five largest e-commerce markets by sales – China, the United States, the United Kingdom, Japan, and Germany – each illustrate the interplay between booming online shopping and packaging usage. Below, we examine each country’s e-commerce scale, how that translates into packaging and parcel volume, and notable initiatives by companies or government to manage the sustainability of all those packages.

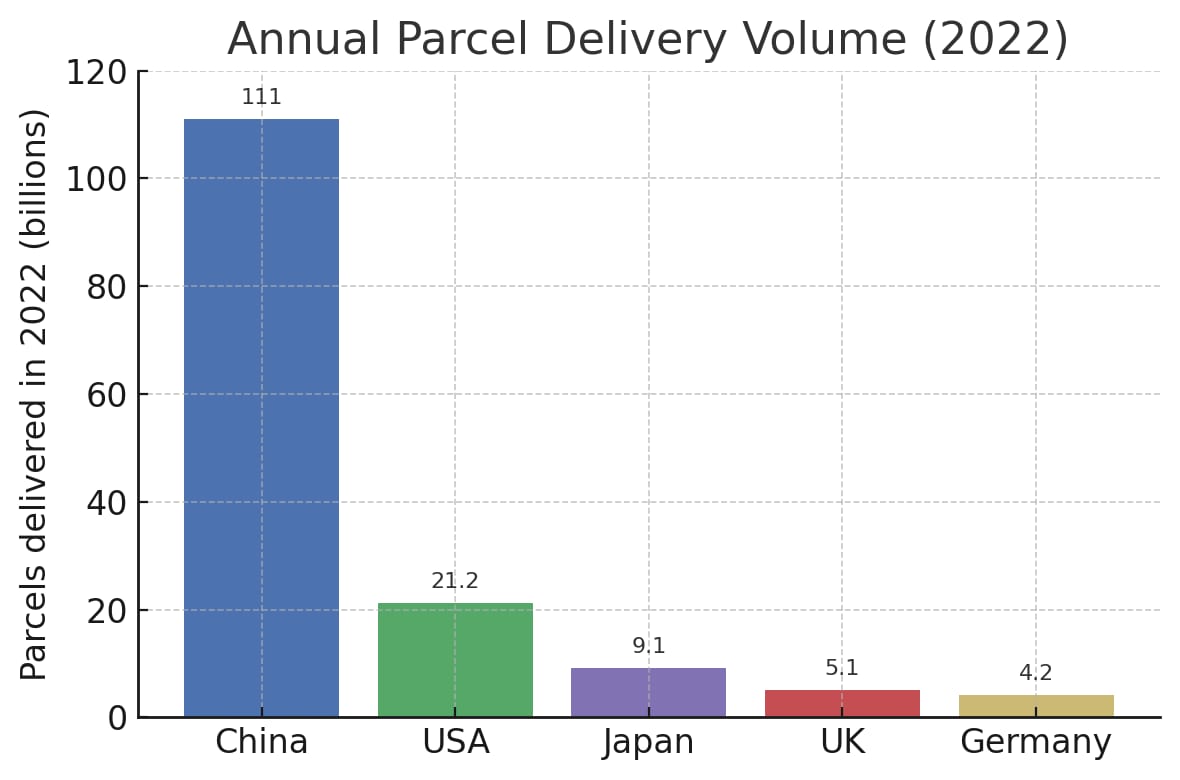

Figure 2: Annual parcel delivery volume in 2022 for top e-commerce markets (billions of packages). China’s parcel shipments are an order of magnitude higher than other countries, reflecting its e-commerce dominance. The U.S., Japan, UK, and Germany each ship billions of parcels yearly.

China: The E-Commerce Giant and Its Packaging Implications

China is by far the world’s largest e-commerce market, with online retail sales that reached around ¥15.5 trillion in 2024 (US$2.16 trillion). In 2023, China’s e-commerce sales were over $3 trillion – roughly three times the U.S. market – and represented nearly half of all retail purchases in the country. This enormous volume is fueled by platforms like Alibaba’s Tmall and Taobao, JD.com, and Pinduoduo, which serve hundreds of millions of shoppers. The sheer scale is illustrated by China’s parcel delivery statistics: in 2022, China’s couriers delivered about 111 billion parcels. By mid-2024, China had already handled its 100-billionth parcel of the year (reaching that milestone 71 days earlier than the previous year). This equates to 440 million packages per day, or roughly 71 packages per person per year in China – an astounding figure that underscores how ingrained online shopping has become in daily life.

Supporting this deluge of packages is a massive packaging industry. China is a leading producer of paper and corrugated board; major firms like Nine Dragons Paper and Lee & Man manufacture millions of tons of containerboard (the paper used in corrugated boxes), much of which goes into e-commerce packaging. E-commerce has created new logistical challenges in China: packages must travel vast distances across provinces and through dense urban areas. They often get handled by scooter delivery in the “last mile” to customers. As a result, durability of packaging is critical – and Chinese consumers have experienced issues with inadequate packaging or damage. Leading e-retailers have responded by improving packaging quality and sustainability. For example, Alibaba’s logistics arm Cainiao and JD Logistics have both launched “green logistics” programs. These include using reusable plastic delivery boxes (for deliveries to pick-up stations, which can be returned and reused) and deploying more recyclable packaging materials. Cainiao has built out an entire end-to-end green supply chain, with initiatives spanning from order placement to recycling. According to the company’s 2024 ESG report, Cainiao’s digital tools for packaging optimization (like smart algorithms that calculate the right box size for each order) helped cut 156,000 tons of carbon emissions in one year. Cainiao also introduced a “Green Circular Box” – a reusable shipping box embedded with an RFID chip to track its usage cycle. By digitally tracking these durable boxes, they can be used many times, reducing single-use cardboard waste. In FY2024, Cainiao reports it recycled or reused 47.6 million cardboard boxes through its warehouses’ take-back programs. The Chinese government is nudging this progress along with policy: it has implemented bans on certain single-use plastics in packaging and encourages couriers to use recyclable or biodegradable materials.

Despite these efforts, China faces a packaging waste challenge commensurate with its e-commerce scale. The corrugated packaging used for billions of parcels puts pressure on resources (demand for pulp, water, etc.) and on waste management systems. Recycling infrastructure in China is still developing – traditionally, China imported waste paper from other countries to recycle, but that ceased in 2021, so domestic collection had to ramp up. Now, an army of informal recyclers and new municipal programs work to collect the mountains of cardboard generated by Taobao and JD deliveries. The opportunity, however, is clear: with e-commerce packaging so critical, China has a chance to “leapfrog” to more sustainable practices via tech and scale (e.g. AI-optimized packaging, large-scale material recycling, and consumer education on returning or recycling packaging). Alibaba and JD’s initiatives, alongside startups working on innovative materials (such as mushroom-based packaging for cushioning), suggest that China’s e-commerce juggernaut could also become a leader in sustainable packaging solutions.

United States: Volume and Innovation in Packaging

The United States is the world’s second-largest e-commerce market. Americans spent about $1.16 trillion online in 2023, which is roughly 16% of total U.S. retail sales. This represents a dramatic rise over the past decade – U.S. e-commerce sales were around $500 billion in 2018, so online volume has roughly doubled in five years. The U.S. e-commerce sector is led by Amazon (which alone accounted for about $130 billion in e-commerce revenue in 2023), with other major players like Walmart.com, eBay, and Target’s online store contributing. This huge market generated about 21.5 billion parcel shipments in 2023 (approximately 65 packages per person for the year). The country’s parcel volume, while much smaller than China’s, is still massive – the U.S. handled on the order of 20–22 billion packages annually in 2021–2023. Notably, after a pandemic surge, U.S. parcel shipments have plateaued or grown modestly, but remain at very high levels (over 20 billion/year compared to ~12 billion in 2014).

This relentless flow of packages has spurred American companies to rethink packaging. Amazon, as the largest e-commerce company, has been a major trend-setter. It ships billions of packages per year (an estimated 7–8 billion globally in 2021) and has faced public pressure over packaging waste (the piles of Amazon boxes at American curbsides have become a common sight). Amazon’s response has been a series of packaging initiatives under its “Frustration-Free Packaging” program and sustainability roadmap. For example, Amazon introduced “Ships in Own Container” (SIOC) certifications to encourage suppliers to design product packaging that doubles as the shipping package (eliminating the need for an outer box). By 2022, Amazon reported that 11% of its packages shipped without any additional Amazon-branded box (i.e. the item’s own package served as the mailer). It also heavily increased the use of flexible mailers (like padded envelopes) for suitable items – in 2022, about 49% of Amazon’s deliveries were in mailers, up from 42% in 2021, while the share shipped in corrugated boxes dropped to 40%. This shift reduces wasted space and shipping costs, since envelopes are lighter and smaller than boxes.

Importantly, Amazon is phasing out plastic packaging in favor of paper. In 2023 the company announced it will eliminate plastic padded mailers in its fulfillment network, switching to recyclable paper padded mailers. In the U.S. and Canada, Amazon had already replaced 99% of mixed-material padded bags (plastic+paper) with all-paper padded mailers as of 2022. The move was partly driven by consumer feedback that customers want sustainable alternatives to plastic mailers. Likewise, major retailers like Walmart have begun switching from plastic to paper mailers and right-sized cardboard boxes to cut packaging waste. These efforts resonate with U.S. consumers’ growing environmental awareness.

From a material standpoint, the U.S. relies heavily on paper-based packaging for e-commerce. American packaging companies such as International Paper, WestRock, and Packaging Corporation of America produce millions of tons of containerboard annually, much of it for e-commerce boxes. Cardboard remains cost-effective and over 90% of Americans have access to curbside recycling for paper, making it a logical choice for mass deployment. Recycling rates are high – according to the American Forest & Paper Association, around 68% of all paper and 74% of corrugated cardboard in the U.S. is recycled each year. So, while the U.S. produces a lot of packaging waste by volume, a large portion of the fiber gets recovered and re-used in new packaging.

U.S. companies are also pushing lightweighting and optimization. Amazon says it has cut the average packaging weight per shipment by 41% since 2015 through package design improvements and materials changes. Using machine learning, they determine the smallest possible box or mailer that fits an order, to eliminate empty space. This not only reduces material use but also addresses shipping costs (most U.S. carriers now charge by size as well as weight – so-called dimensional weight pricing – so sending half-empty boxes incurs a penalty). Other retailers and package carriers in the U.S. are following suit by investing in automated packing machines that custom-cut corrugated sheets to exactly the right size carton for each order.

Despite progress, challenges remain in the U.S. One is consumer recycling behavior – not everyone breaks down and recycles their boxes. Another is the prevalence of plastic packaging for certain uses (for instance, many apparel orders still ship in plastic polybags). Plastic air pillows and bubble wrap are also common for void fill. While these are lighter than paper, they are less sustainable unless recycled via special programs (few curbside programs accept plastic film). Pressure from advocacy groups is mounting: in 2022, Amazon shareholders filed a proposal urging the company to quantify its plastic packaging usage and set reduction targets. Although the resolution didn’t pass, Amazon did acknowledge the concern and pointed to its ongoing plastic reduction efforts. Similarly, U.S. state and local governments are considering regulations – for example, some states have plastic packaging bans or fees, and there’s interest in Extended Producer Responsibility (EPR) schemes that would make companies financially responsible for managing packaging waste.

Overall, the U.S. e-commerce sector is a hotbed of packaging innovation: from materials (biodegradable packaging peanuts made of cornstarch replacing Styrofoam, mushroom-based packaging for high-end electronics, recyclable insulated box liners for grocery delivery) to processes (more efficient pack-out, and perhaps soon drone or robot delivery which could enable new packaging forms). The combination of high parcel volume and consumer/environmental expectations ensures that the U.S. will continue to evolve its packaging approach, likely with fiber-based packaging at the core due to its proven sustainability advantages.

United Kingdom: High Online Penetration and a Push for Sustainability

The UK is the third-largest e-commerce market by sales, reaching approximately $196 billion in 2023 (around £150 billion). What’s striking about the UK is its very high e-commerce penetration: roughly 30% of all retail sales in the UK occur online, one of the highest rates in the world (only China and South Korea rival the UK on this metric). British consumers embraced online shopping early, and the market includes not just Amazon UK but also strong local players (supermarkets like Tesco and Sainsbury’s have huge online grocery operations, for example). With a population of ~67 million, the UK’s per-capita online spending is among the highest globally.

This translates into a significant volume of packages relative to the country’s size. The UK shipped about 5.1 billion parcels in 2022, down slightly from 5.4 billion in 2021 (a pandemic peak). That’s roughly 75 parcels per person per year in Britain. The delivery market is served by Royal Mail, Hermes (Evri), DPD, DHL and Amazon Logistics, among others. In fact, Amazon has rapidly grown its in-house delivery in the UK, reflecting the broader trend of e-commerce companies building their own logistics networks.

On the packaging front, the UK heavily relies on paper-based packaging and is a leader in sustainable packaging initiatives. British packaging companies like DS Smith and Mondi are at the forefront of designing eco-friendly solutions for e-commerce. DS Smith, for example, has an entire division for e-commerce packaging and has published Circular Design Principles to guide creating packages that use no more material than necessary and are easy to recycle. They’ve introduced innovations such as 100% recyclable cardboard envelopes (to replace plastic poly mailers) and a glue-less cardboard box that can be folded up for returns. DS Smith’s research on consumer attitudes found UK shoppers are very sensitive to packaging issues: as noted earlier, 26% will shun a retailer over excessive packaging and 22% if packaging isn’t recyclable. Additionally, 68% of UK consumers say a company’s sustainability reputation is enhanced if their parcel arrives in paper-based packaging instead of plastic. These sentiments are pushing UK retailers to eliminate things like plastic fillers and to “right-size” packages to avoid large boxes for small items. There’s also a notable dislike of overpackaging in the UK – 45% of online shoppers cited a preference for minimal packaging (no extraneous empty space or layers).

Policy is another driver. The UK government implemented a Plastic Packaging Tax in April 2022, which charges companies £200 per tonne of plastic packaging that contains less than 30% recycled plastic. This effectively incentivizes businesses to either use higher recycled content in plastics or switch to other materials like paper. The UK is also rolling out Extended Producer Responsibility rules for packaging, meaning producers will bear more of the cost of collecting and recycling packaging waste. Such regulations, along with EU directives (which the UK often mirrored when it was an EU member), are accelerating a shift toward fiber-based packaging and the reduction of single-use plastics. For instance, many UK e-commerce firms now ship apparel in paper mailing bags instead of polyethylene bags, and use paper tape instead of plastic tape on boxes to ensure the whole package is curbside recyclable.

The UK’s recycling infrastructure for paper packaging is well-developed. The country recycles about 80% of all paper and cardboard packaging. Consumers are accustomed to breaking down boxes for council collection. However, the explosion of parcels has led to surges in recycling volumes, which local authorities have had to manage. Some councils have issued guidance to residents on how to handle the glut of cardboard (for example, asking that boxes be flattened and kept dry).

From a corporate perspective, major UK retailers are making packaging pledges. Supermarkets offering online delivery have targets to reduce plastic and use compostable or recyclable alternatives. For instance, Tesco aims to remove millions of pieces of plastic by redesigning packaging for online orders (like eliminating secondary plastic bags for delivered groceries). Amazon UK similarly participates in Amazon’s global initiatives – UK customers now often receive items in “frustration-free” cardboard packaging without any plastic, and Amazon has been trialing package-free deliveries for certain products (shipping with just a label on the manufacturer’s box).

One interesting trend in Britain is experimentation with reusable packaging systems. Some startups have tried models where customers can opt to receive goods in a reusable box or tote that they later return (though this is still niche and faces cost hurdles). Additionally, parcel carriers in the UK have introduced services for collecting packaging for recycling upon delivery (e.g., taking back the cardboard box from a large appliance delivery). These reflect a broader culture in the UK of environmental consciousness and the circular economy ethos.

In summary, the UK’s high e-commerce usage has made it a testbed for sustainable packaging practices. Fiber-based packaging is standard, and both consumer pressure and government policy ensure that companies keep pushing for less wasteful, more recyclable packaging. UK packaging firms like DS Smith and Smurfit Kappa (though based in Ireland, a big player in the UK market) will continue playing a key role in innovating new solutions to serve the online retail sector while minimizing environmental impact.

Japan: A Mature Market Emphasizing Quality and Efficiency

Japan ranks among the top e-commerce markets globally, with about $193 billion in e-commerce sales in 2023. E-commerce accounts for roughly 13–14% of Japan’s total retail sales – a lower share than in China, the UK, or South Korea, but it has been gradually rising. Japanese consumers historically have valued in-person shopping (and Japan has a dense network of convenient stores and malls), but online shopping has made significant inroads, especially in categories like electronics, fashion, and increasingly groceries. Major domestic e-commerce platforms include Rakuten and Yahoo! Japan Shopping, alongside Amazon Japan which has captured a large share of the market.

In terms of parcel volume, Japan saw about 9.1 billion parcels and packets delivered in 2022, essentially flat from 9.2 billion in 2021. That’s roughly 73 parcels per person per year in Japan – comparable to the UK and a testament to how pervasive parcel delivery is in daily life. Japan’s delivery logistics (often via companies like Yamato Transport, Sagawa Express, and Japan Post) are famously efficient and reliable, with services like takuhaibin (home delivery) having been popular even before e-commerce (for sending gifts, luggage, etc.). The existing culture of frequent parcel delivery helped e-commerce ramp up smoothly in Japan. It’s not uncommon for Japanese consumers to receive multiple small packages per week, delivered to homes or convenient pickup points, which impacts packaging needs.

One hallmark of Japanese retail, both offline and online, is meticulous packaging and presentation. There is a cultural emphasis on neatness and protecting the product (customers expect items to be well-packaged to avoid any damage or blemish). As a result, Japanese e-commerce packages have traditionally included ample cushioning, double packaging, and sometimes extra wrapping – which, while ensuring quality, can lead to waste. However, this is changing as awareness of sustainability grows. The Japanese government and industry have started encouraging reductions in packaging. For example, Japan has set targets to cut plastic waste and promote recycling; a law in 2020 requires businesses to reduce the use of single-use plastics (including in packaging) and to label plastic materials clearly for recycling.

Paper-based packaging is widespread in Japan’s e-commerce. Much like elsewhere, cardboard boxes are the default for shipping, and Japan has a robust domestic paper industry (companies like Oji Holdings, Rengo Co., and Nippon Paper) that supplies corrugated materials. Rengo Co., in fact, is a major producer of corrugated board and has seen growth in demand due to e-commerce – they have expanded capacity and acquired new facilities to keep up. Japan also has unique packaging solutions like small ”Yu-Packet” or “Letter Pack” envelopes (offered by Japan Post) for e-commerce items, which are often sturdy paperboard mailers that fit through mail slots. These have become popular for shipping books, cosmetics, and other compact items.

On the sustainability front, Japan recycles a high percentage of paper – the recycling rate for paper and cardboard packaging was about 85% as of a few years ago. Streets in Japan are notably clean, and there is a strong habit of sorting and recycling packaging. Many delivery services in Japan will actually take back the shipping box from the customer at the time of delivery if requested, to recycle it. Rakuten, one of the largest e-commerce companies, has partnered with local governments to set up programs to collect and recycle used packaging from customers. Additionally, some Japanese retailers have started to use biodegradable or compostable materials for filler instead of plastic bubble wrap. For instance, clothing shipments might use thin paper wrapping instead of plastic.

A notable challenge in Japan is reducing overpackaging while maintaining quality. Some progress has been made: Amazon Japan, for example, introduced options at checkout for “minimal packaging” for certain items, and has cut down on extra wrapping inside the box for its own shipments. There are also experiments with packaging-free delivery – for instance, convenience store pickup of items that come just with a product tag, no outer box (though this works only for durable items). Japanese consumers are adapting to these changes, driven by a broader societal push toward environmental responsibility. Campaigns around the concept of mottainai (meaning “don’t waste”) resonate with reducing unnecessary packaging.

In terms of innovations, Japan has seen some neat ideas: a company developed a self-expanding paper cushioning that can replace plastic bubble wrap by expanding when unwrapped. Also, Japan’s expertise in materials science has led to better recyclable plastics and improved paper strength (allowing for lighter weight boxes that still protect goods). Toyo Seikan and other firms are researching coatings that could make paper packaging resistant to moisture and oil so that even more product categories (like liquid or greasy items) can ship plastic-free.

Overall, Japan’s e-commerce packaging landscape is one of high-quality expectations balanced with a growing sustainability ethos. As a mature market, growth is slower, but that also means companies can focus on optimization rather than sheer scale. We can expect Japanese retailers to continue refining their packaging – likely leveraging the country’s strengths in engineering and hospitality to create solutions that are both environmentally friendly and pleasing to the customer.

Germany: Large Market Adopting Circular Practices

Germany is Europe’s largest economy and one of the top e-commerce markets, with about $97 billion in e-commerce sales in 2023 (roughly €90 billion). German online retail ranges from giants like Amazon Germany (which is the dominant player) and Otto.de to a multitude of specialized online stores. E-commerce is slightly less penetrated in Germany compared to the UK – recent estimates put German e-commerce at around 15% of retail sales in 2024 – but it has been steadily growing. Notably, Germany saw a slight dip in e-commerce revenue in 2022 (post-pandemic) but returned to growth in 2023.

In terms of parcel volume, Germany handled about 4.2 billion parcels in 2022, down 7% from 4.5 billion in 2021. This works out to roughly 50 parcels per person per year. The German parcel delivery market is highly developed, with DHL (part of Deutsche Post) being the largest carrier – DHL alone delivered about 2.0 billion parcels in Germany in 2022. Other key carriers include Hermes, DPD, GLS, and UPS. Amazon has also started building its logistics network in Germany, but to a lesser extent than in the US or UK (DHL remains the backbone for a lot of Amazon’s deliveries in Germany, as evidenced by DHL’s large market share).

Germany has a long history of leadership in environmental policy and recycling, which extends to packaging. It was one of the first countries to implement a packaging waste law (the “Verpackungsverordnung” in the 1990s) and the Green Dot (“Grüner Punkt”) system, which required producers to take responsibility for packaging waste and set up an infrastructure to recycle it. Shoppers in Germany are used to sorting their recyclables diligently – paper, glass, packaging, etc., often into separate bins. As a result, Germany today has one of the highest packaging recycling rates in the world. For paper and cardboard packaging, recycling rates in Germany are typically around 80% or higher, in line with the EU average.

For e-commerce packaging, this means the fiber from all those parcel boxes is largely reclaimed. Indeed, one could say Germany has a fairly circular system already for paper: consumers flatten the used boxes, put them in the blue bin, and they get recycled into new paper products by German paper mills (Germany is a major paper recycling and producing country in Europe). This significantly mitigates the environmental impact of e-commerce growth – the carbon footprint of a recycled cardboard box is much lower than that of a new one, and landfill contribution is minimized.

German consumers also have a relatively low tolerance for waste. There’s a cultural emphasis on efficiency and no-nonsense functionality. Excessively large or unnecessary packaging may not sit well with German shoppers (similar to their British counterparts). Some evidence: the logistics company Hermes found that many German customers were irritated by receiving tiny items in big boxes, and this has pushed retailers to adopt automated packing machines that right-size boxes for each order. Moreover, in Germany, overpackaging can actually lead to higher costs due to the way shipping is priced (carriers like DHL in Germany also use dimensional weight formulas). So there’s an economic incentive to eliminate empty space in parcels.

The German government updated its packaging law (VerpackG) in recent years to further enforce producer responsibility. As of July 2022, even e-commerce businesses outside Germany shipping into the country must register and contribute to recycling fees for their packaging. This ensures that online retailers (domestic or foreign) fund the recycling of the packaging they send to German consumers – a strong EPR mechanism. Additionally, Germany has banned certain single-use plastic items and set targets for reducing plastic packaging.

In practice, many German e-commerce shipments use only paper-based packaging or easily recyclable plastic. For instance, Amazon Germany has largely switched to paper mailing bags for books and small items and reduced use of plastic tape on its boxes (using a single paper strip where possible). Some retailers encourage customers to return packaging for reuse – one outdoor apparel retailer in Germany sends products in reusable zip bags that customers can send back, to be used again. There are also startups offering reusable shipping boxes (often foldable plastic crates that can be used dozens of times) for e-commerce; a notable one was promoted by the German postal service in a pilot, although scaling such a system remains challenging.

Germany is also home to major packaging companies like Mondi (which has large operations in Germany) and Smurfit Kappa (with several plants serving Germany). These companies supply the corrugated packaging for many e-commerce businesses and invest in R&D for better materials – for example, Mondi has developed paper-based padded mailers as an alternative to bubble mailers, specifically targeting the e-commerce market’s need for lightweight protection. Another German innovation is in adhesives and coatings that enable packaging to be both secure and easily recyclable (Germany’s Henkel, for example, makes special packaging adhesives that don’t contaminate recycling).

In summary, Germany’s e-commerce packaging scene is characterized by a strong recycling loop, regulatory support for sustainability, and industry innovation. The challenges ahead will be managing continued growth without increasing waste (Germany already had very high packaging waste per capita – partly because of high consumption – but it compensates with high recycling). As online grocery grows, there will be more need for insulated packaging, which is an area where sustainable options (like wool liners or recyclable insulation) are being explored. But given Germany’s track record, it’s likely to remain at the forefront of implementing a circular economy approach to e-commerce packaging.

Industry Insights: Packaging and E-Commerce Companies

Across these top markets, both packaging producers and e-commerce companies are adapting rapidly. Major packaging firms have aligned their strategies to serve the e-commerce boom with sustainable products. International Paper, the largest global producer of corrugated packaging, stated that its goal is to “make the world safer and more productive, one sustainable package at a time,” and it has poured investment into capacity and innovation for e-commerce. The company’s European arm boosted production by 60% at key plants to supply “more sustainable corrugated packaging” for online retail. Similarly, DS Smith has shifted much of its product development to e-commerce solutions – offering packaging design services to brands to optimize for shipping, and even setting up an Innovation Hub for online retail packaging. DS Smith reports that it has helped companies reduce unused space in parcels by redesigning over 100,000 packaging layouts, eliminating thousands of truck trips and tons of carbon. Other packaging giants like Smurfit Kappa (Ireland), Mondi (UK/Austria), WestRock (USA), and Oji (Japan) are all expanding their e-commerce-focused offerings, from easy-fold boxes for quick assembly in warehouses to high-quality printable boxes that double as “brand advertising” when they arrive at the customer (a trend known as “unboxing experience”).

On the e-commerce retailer side, initiatives abound to balance cost, customer satisfaction, and sustainability:

Amazon, as discussed, is a leader in package innovation (frustration-free packaging, SIOC, plastic-free mailers). It claims that globally these programs eliminated over 1.5 million tons of packaging material since 2015. Amazon also reports that currently about 92% of the packaging material by weight in its North American operations is recyclable via curbside programs – thanks to the dominance of paper and corrugate. Amazon’s next frontier is perhaps reusable packaging for groceries (Amazon Fresh totes) and expanding its zero-packing “Just Walk Out” stores concept to e-commerce deliveries.

Alibaba and JD.com in China are leveraging technology and scale. They collectively ship tens of millions of packages per day and have implemented AI in warehouses to cut down on wasted material. Cainiao (Alibaba) not only introduced the RFID reusable box, but also set up over 80,000 packaging recycling stations across China where consumers can drop off used boxes and padded envelopes for reuse or recycling. JD.com pioneered using biodegradable packaging peanuts made from cornstarch in place of styrofoam for fragile shipments, and it runs a “Green Stream Initiative” which has reportedly saved hundreds of millions of cardboard boxes through reuse programs. Both Alibaba and JD have public commitments to use more recycled content in packaging and to curb plastic – spurred by government guidance.

Traditional retail companies going omni-channel (like Walmart, Target, Tesco, Carrefour) are also now major e-commerce shippers and are bringing their sustainability pledges into their fulfillment centers. For example, Walmart aims for 100% recyclable packaging for its private-label e-commerce shipments and has begun using paper mailers and recyclable padded paper envelopes instead of bubble mailers. European retailers like Zalando and Zara have switched from plastic to paper delivery bags. Many fashion retailers are also exploring take-back schemes for packaging, considering that apparel often has high return rates (so a durable reusable mailer could make sense if the item might be sent back).

Logistics and parcel companies themselves are advocating for smarter packaging. UPS and FedEx publish guidelines for optimal packaging to reduce damage (which indirectly encourages better quality materials and adequate cushioning). DHL has a GoGreen program advising e-commerce clients on how to cut emissions – one tip is “pack smaller and lighter” to fit more parcels per truckload. In Germany, DHL even sells branded “DHL Packsets” (standardized boxes made of recycled paper in various sizes) to customers, implicitly pushing the idea of using the right size box.

Challenges and Innovations in Sustainable Packaging

Despite great strides, significant challenges remain in making e-commerce packaging truly sustainable globally. Here are some of the key issues and how the industry is tackling them:

Packaging Waste and Consumer Perceptions: The flood of parcels means a flood of waste for consumers to deal with. Consumers in many countries have complained about the piles of boxes and packaging materials they must discard or recycle. In a Freedonia survey, some shoppers even cited the “difficulty of dealing with numerous shipping boxes and packaging waste” as a reason they might return to physical stores. This puts pressure on e-commerce companies to simplify packaging (for example, to avoid using five different material types in one box that the consumer has to separate). It also has led to ideas like branded recycling incentives – e.g., give customers loyalty points if they return a certain number of boxes to a store or driver for recycling. Some municipalities are exploring dedicated recycling programs for e-commerce packaging (special pickups, etc.). The challenge is acute in apartment-dense cities where disposal space is limited. Innovation in this area is not so much high-tech as it is logistical and educational: making recycling easier and engaging consumers to participate.

Recycling Infrastructure Gaps: Not all countries (or regions within countries) have robust recycling for packaging. For instance, in some developing markets where e-commerce is growing (like India, Southeast Asia), the waste management systems struggle to handle the additional volume of corrugated fiber. The lack of proper recycling infrastructure can be a major bottleneck. To address this, companies and governments are starting to invest in improving collection and recycling. In India, the government banned certain single-use plastics and is pushing companies to use paper or compostable alternatives – but concurrently, recycling systems for paper and new composting facilities need expansion. Global organizations and industry coalitions (like the Alliance to End Plastic Waste, or the Paper Recycling Coalition) are funneling funds into infrastructure projects. One innovative approach is mobile recycling units that can be deployed in high-delivery neighborhoods to compact and collect cardboard efficiently. Also, digital apps are emerging that connect consumers with recyclers (for example, an app where you can schedule a pickup of your used boxes by a local recycler for a small fee – thus creating informal recycling incentives).

Balancing Protection with Sustainability: Packaging’s first job is to protect the product. If an item arrives broken, its environmental footprint worsens (due to the need for a replacement shipment, wasted product, etc.). So e-commerce packagers must ensure materials are robust enough while avoiding excess. This can be challenging for certain goods: e.g., electronics, which are fragile and often shipped individually. Multi-layer packaging (product box, then foam inserts, then outer box) is often used, generating waste. Innovations here include better shock-absorbing designs using paper – such as molded pulp cushions custom-shaped for an item – and airbag systems that can be reused. Some companies use inflatable plastic cushions but are looking to switch to inflatable paper bubbles or other recyclable options. Additionally, research into bioplastic foams or compostable foam peanuts is ongoing to replace petroleum-based foams. The goal is a lightweight, compostable material that can cushion as effectively as Styrofoam. Another tactic is simply reducing empty space: if a box is well-fit to the item, less filler is needed, which is a win-win.

Cost and Material Trade-offs: Sustainable packaging alternatives can be more expensive. Bio-based or innovative materials are often produced at smaller scale than conventional materials, keeping costs high. As one report noted, “higher upfront costs make adoption difficult for SMEs” (small merchants) in e-commerce. A small online seller might opt for a cheap plastic mailer to save pennies, even if a paper mailer is better for the planet. Overcoming this requires economies of scale and perhaps subsidies or regulation. We are seeing costs come down as demand increases – for example, recycled paper mailers are now quite affordable. Some governments are introducing penalties for unsustainable choices (like the UK plastic tax), which tilts the cost calculation. Larger companies are also helping drive scale: when Amazon orders millions of paper padded mailers, it helps build supply that others can then tap into. Innovation in materials – such as developing coatings or additives that allow thinner paper or more recycled content without sacrificing strength – also helps reduce costs by using less material. Ongoing R&D by packaging companies aims to create the next generation of “lightweight but strong” corrugated board, possibly incorporating things like nanocellulose or new fiber mixes.

Plastic Reduction and New Materials: A major challenge is replacing plastics where they are still prevalent. This includes plastic mailing bags, bubble wrap, tape, and the clear plastic pouches for shipping labels used on boxes. Companies are addressing each of these: switching to paper packing tape (which is now common – it has fibers and an adhesive that are both paper-recyclable), developing water-soluble or bio-based packing peanuts as mentioned, and even testing seaweed-derived bioplastic films for protective wrap. One interesting innovation is mushroom packaging: a material grown from mycelium (fungal roots) and agricultural waste that forms a foam-like structure. It’s being piloted for shipping high-value fragile items (like glass bottles, electronics); once unpacked, it can be composted at home. There are still scalability issues – growing packaging is not as quick as manufacturing it – but it’s a glimpse of a radically different approach. Seaweed-based packaging films are also in early use, mostly for small sachets or filler, and are attractive because they biodegrade quickly if they end up as litter. The key will be ensuring these novel materials can be produced in the quantities needed for mass e-commerce and that they perform reliably.

Reusable Packaging Models: Truly cutting waste might involve moving away from single-use packaging altogether for certain loops. Reusable packaging (durable boxes or envelopes) is a promising idea – if each package can be reused 10 or 20 times, that’s 90-95% reduction in waste. The challenge is the reverse logistics: getting the empty package back and doing so in a cost-effective way. Some innovations here include RFID or QR code tracking (as Cainiao is doing with its reusable box), deposit systems (customer pays a small deposit for a reusable box and gets it back upon return), and modular box designs that can adjust to different sizes (reducing the number of box types needed). Pilot programs, like one in Finland and another in France, have shown consumers are willing to return packaging if it’s easy (drop at mailbox or pickup by courier). If e-commerce continues to grow, we may see closed-loop networks for packaging emerge – perhaps run by postal services or third parties – which could significantly cut the demand for new packaging production.

Conclusion

Paper, pulp, and packaging may not be the flashiest components of the online shopping revolution, but they are absolutely foundational. The top e-commerce markets – China, the U.S., the U.K., Japan, and Germany – illustrate how the growth of online retail has intertwined with the packaging industry on a global scale. Each of these countries, in its own way, is pushing the envelope (quite literally) on packaging technology and sustainability. From China’s 100-billion-parcel delivery juggernaut spurring reusable box innovations, to the United States’ tech-driven packaging optimization, to Europe and Japan’s emphasis on recyclability and waste reduction, the trajectory is clear. E-commerce will continue to expand, and with it the responsibility to manage materials wisely.